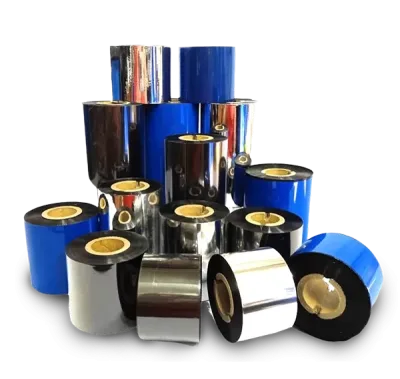

Sinazza Imaging Products

ISO 14001 : 2015 Certification

Fast Delivery (Malaysia) within 48 hours

Technical Support : Helps Troubleshoot within 48 working hours

Factory-Direct Pricing

Customized Size Options

Ribbons Made in Japan / USA

Low MOQ

Enquire Us

Feel Free To Reach Out To Us